Thought piece by StrongArm Tech’s CEO and Founder, Sean Petterson.

Every year in the US, over $250B is spent on workplace injuries. The total cost of illnesses, injuries and deaths amounts to 3.94% of the global GDP ($2.99 Trillion). This is not a little problem. It’s an epidemic. And what keeps me up at night is that behind these numbers are lives that are derailed– a provider on the couch, a family without a chance.

To make things even worse, with the rise of E-Commerce and the corresponding growth of distribution operations, the problem will compound over the next few years unless something is done.

We grew up seeing people like our fathers endure preventable physical pain on their bodies while providing for their family. “Manual laborers” or “blue collar workers”, unlike sporting athletes, have been overlooked in an age of rapidly evolving design and technology equipment. We didn’t want to standby and watch this injustice continue to impact the backbone of society, the lifeblood of our economy, the people who build the world around us. That is why we started StrongArm nearly 7 years ago, to keep Industrial Athletes™ Proud, Protected and Productive. After 5 product families, 33 patent filings, countless university, government and international research, our aim is unchanged. The mission is the same.

The good news is that we’ve seen some big shifts that help us in the pursuit of this mission. Primarily, we’ve seen corporate leadership teams begin to make safety and injury prevention a top priority. This is not solely a charitable decision – it’s simply dollars and cents in a world where unemployment levels are historically low and corporate giants are pushing the demands of 3PL and supply chain to extreme ends. No matter what the motivation, the end result is beneficial to the world. And confronting and acknowledging the problem of workplace injuries is an important first step.

Yet, in our fight against workplace injuries, two important fundamentals continue to confront us:

- It’s a lack of understanding the problem– not a lack of desire to solve it– that leads to injuries

- Innovation and technology alone cannot replace a strong and meaningful safety culture

Regarding point one, traditionally when a person gets hurt an injury report is filed via an OSHA 300 Log. The information included in this retrospective evaluation is subject to opinion, which can often lead to an inaccurate and ineffectual assessment. This is bad for companies who rely on these reports as a basis for infrastructure changes, investing in employee training, or the purchasing of new equipment. The problem worsens in an insured organization where the insurer, who writes policies based on historical run rate, bases their work on inaccurate data.

Even when attempting to be proactive, risk assessments are done via static and subjective means. The average inaccuracy rates for observation biases are close to 30%. Manual observations, and the costs associated with them, allow for only a small sample size to be considered, and more importantly, there is no way to measure efficacy in terms of ROI. Even on the small number cases where there is a clear ROI, the ability to communicate the improvements and impacts gets lost between lab measurements and front line operations.

These challenges have created significant barriers for innovation in industrial safety because organizations don’t realize that their understanding of their own safety challenges is built on questionable information.

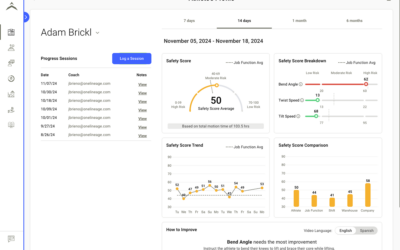

I’m proud to say that over the past couple of years, we’ve developed our best tool yet to confront workplace injuries – the FUSE Risk Management Platform. We saw that continuous monitoring in driver telematics and industrial machine health had unlocked insights towards efficiency in the oldest industries in the world. We applied the same concepts to the most valuable thing in a corporation: human capital. In doing so we’ve been able to take the subjectivity out of injury analysis and conduct complete risk observations on every movement in a facility. If properly integrated into safety management, the FUSE Platform can conquer the lack of understanding that’s so common in organizations across the entire value chain.

Yet, no matter how many bodies we get the FUSE on, and no matter how strong the data we provide, that second point still confronts us– innovation cannot replace a strong safety culture. We’ve seen organizations who use the FUSE Platform– the best reporting and actionable safety insights possible- but don’t prioritize safety internally. In turn, they don’t see the safety improvements that most customers have been able to realize with the FUSE (on average >30% YoY reduction in injury rates). I suspect that no matter what these companies do, they will never see safety improvements until they make a top to bottom commitment to change their culture and make safety everyone’s responsibility.

At the end of the day, StrongArm makes a tool and provides a service. To fully realize our mission, we need partnership. We need partners at all levels of organizations to buy into this belief that there is a better way to understand safety. We need partners to realize that safety creates long term productivity, engagement and retention. We need partners who are ready to throw out the old playbook and embrace the idea that we can get out in front of injuries, focusing on being proactive rather than reactive.

If you and your organization can make that mental leap, I want to hear from you. We’re actively looking for new partners. Our technology is affordable, small and simple to use. My team is passionate and experienced at easy implementation and driving results. And most of all, YOU can empower your team of Industrial Athletes™ to be Proud, Protected and Productive. And that, after all, is why StrongArm exists.