In the fast-paced world of food redistribution, Dot Foods, Inc. faced a pressing challenge: how to effectively train a new workforce that varied widely in experience and skill levels. Recognizing the need for a more personalized and effective training approach, the company partnered with StrongArm Technologies to implement their SafeWork program, aiming to improve injury prevention and training methods.

Keep reading to learn why the Dot Foods, Inc. occupational health trainer manager called StrongArm a “key partner in improving our injury prevention programming for new warehouse employees.”

Deployment Strategy: Enhancing Injury Prevention for New Hires

The client’s journey with the SafeWork Platform began in March 2021 with a pilot phase, culminating in a full deployment by February of the following year. The initiative now spans across three distribution centers and leverages 125 sensors to service over 1,000 unique employees.

The SafeWork deployment specifically targets the roles of order selectors for regular and light pick tasks. These positions, crucial to the company’s distribution efficiency, were identified as prime candidates for the enhanced training and safety measures provided by the SafeWork Platform.

StrongArm’s Data-Driven Training Approach

“StrongArm’s sensors help us educate all employees, no matter what their work history or habits, and establish new, healthy movement patterns that aid in their success.”

-Katie Neeley, Occupational Health Trainer Manager at Dot Foods

The SafeWork Wearables Program played a transformative role in the company’s new hire training. Across the three sites, the program involved 1,146 new hires, or “Industrial Athletes,” who actively engaged in 22,615 risk sessions. By analyzing a substantial 187,660 hours of motion data, the program significantly improved workplace safety and efficiency for Dot Foods, Inc. One of the most notable outcomes was observed among athletes who used the device 45 times or more; by StrongArm’s calculation, Dot achieved a remarkable 32% increase in their lift rate coupled with a 30% reduction in risk.

A Collaborative Partnership of Continuous Improvement

“Our relationship with StrongArm has enhanced our prevention programming and allowed us to personalize our approach with new employees.”

-Katie Neeley, Occupational Health Trainer Manager

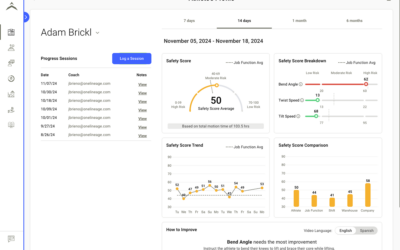

The collaborative partnership between StrongArm and the occupational health training group was a cornerstone of the success achieved. The proactive safety data informed the trainers who should receive personalized training from the occupational health staff, ensuring that each individual’s training was as effective as possible. Moreover, the data provided the trainers with root cause insights and the ability to measure performance improvement. Monthly calls between both teams facilitated the valuable exchange of experiences and ideas. These discussions allowed StrongArm to showcase new features like Progress Sessions and review data from all sites, fostering a culture of continuous improvement and best practice sharing.

Setting a New Standard in Workplace Training

The partnership between Dot Foods, Inc. and StrongArm Technologies sets a new benchmark in the industry for how technology can be leveraged to personalize training for a diverse workforce. The SafeWork program not only enhanced the company’s injury prevention programming but also paved the way for a more adaptive, data-driven approach to employee training.

Ready to enhance your injury prevention programming? At StrongArm, our mission is to keep Industrial Athletes™ safe through our SafeWork Platform — an end-to-end workforce optimization and risk management solution. Our safety wearables are programmed to detect high risk performance. Sensors help Industrial Athletes™ move their bodies safely so they don’t have to think about it, gathering data points while providing real-time haptic feedback to help correct unsafe behaviors.

Contact us today for more information and learn how to create a safer work environment.